OEM

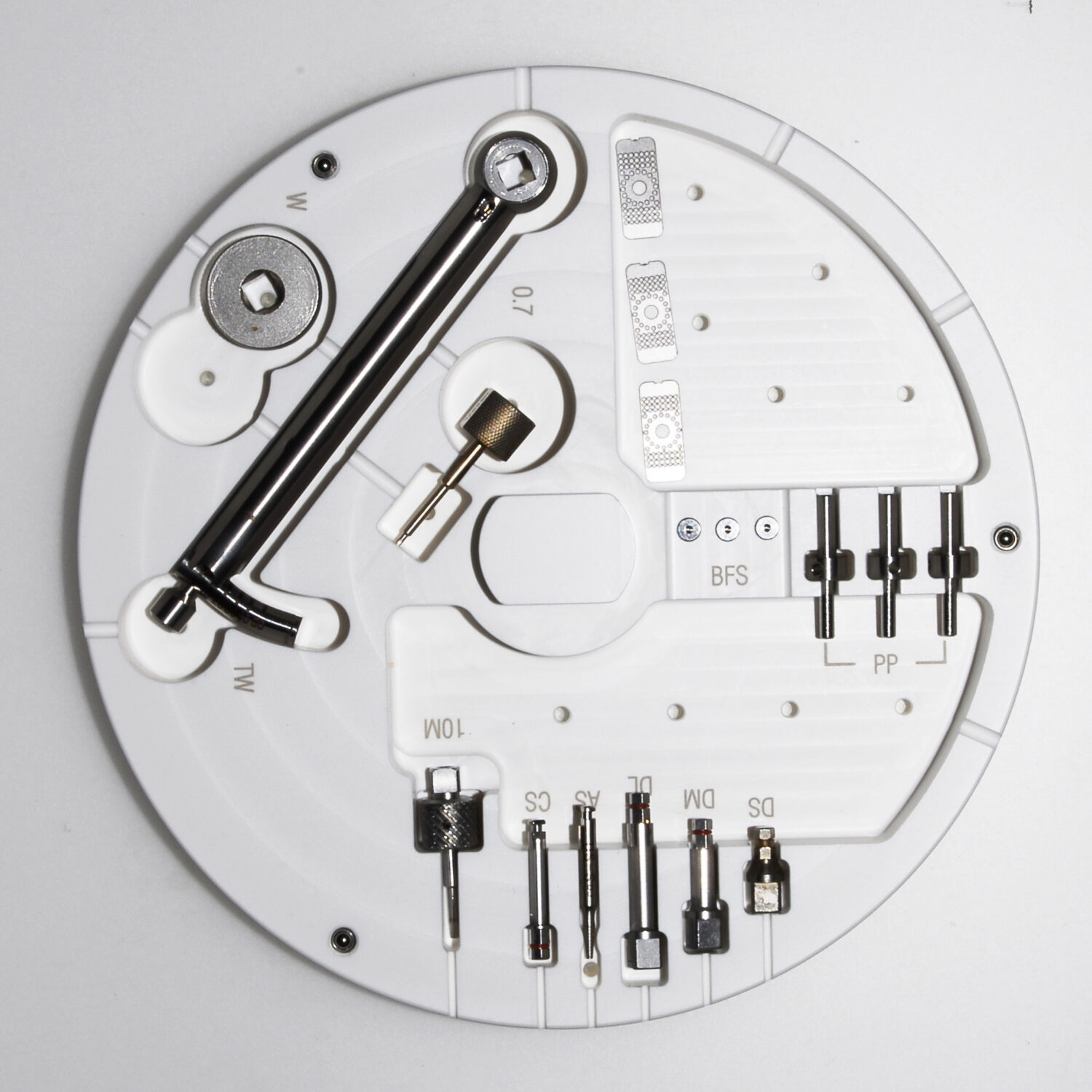

TK IMPLANT TOOL

OEM

TK IMPLANT TOOL

Three features for outstanding sharpness and durability

*No harmful heat is generated in the bone tissue even when cutting without water injection, and sufficient autogenous bone can be collected at the same time as bone cutting.

* 2. For normal bone, there is no need to start with a small drill and gradually increase its diameter and the implantation socket can be created with a single drill of the desired size.

*3. The unique blade shape allows safe drilling without biting even at low RPM.

*1. Limited to low-speed rotation of 50 rpm or less.

*2. When bone density is high, it is recommended to use a drill one or two sizes smaller.

*3. Various methods are used to ensure the sharpness of the drill tip, such as the use of a rake groove on the flat edge of the drill tip and the use of a countersink for cortical bone.

Customer's Voice

Customer's Voice

BIO GRAFT LLC

- Please tell us about your business outline.

- Import, export and sales of dental implants and medical devices. We are also a clinical dentist who has been providing implant treatment since 1988.

- What made you decide to contact us?

- We were introduced by an implant manufacturer with whom we have a business relationship.

- What concerns did you face before contacting us?

- The drills we had been using so far for implant placement were of two types: one with high-speed rotation and water injection, and the other with low-speed rotation and no water injection. Both had their advantages and disadvantages, and we felt very stressed by each. Currently, the mainstream of drills for forming implant placement sockets is the high-speed rotary water injection method. At the time when I started implant treatment, I had no doubts or complaints about this method as I was taught by the implant manufacturer. It is quite natural to inject a large amount of water to control heat generation. However, if there is no heat, there is no need for water injection, and it is a great loss to waste the best biomaterial that can be recovered and utilized by water injection, which is autologous bone. We were also stressed by having to take care of the large amount of cooling water that accumulates in the mouth during implantation procedures during IV sedation. Then we changed to a low-rotation, no-water injection method, which allowed us to collect the autogenous bone, but we had to change many drills. In addition, when a certain number of implants were to be placed, the time required for placement was longer, and the stress and effort were very high.

- Why did you decide to work with us?

- We had been thinking since we heard about DENTECH.

- What are your impressions of our services and products?

- We are very satisfied with the product, which was created based on our image of a safe, secure, and stress-free drill. It took some time to reach the final shape, but when I performed the first implantation surgery with the drill, we were filled with excitement and gratitude that the drill was even better than we had expected. The hard cortical bone can be formed with sharp countersinking. The rest is soft bone marrow, so we collect the autogenous bone in several steps at low speed. A stopper adjusts the depth, so it does not go deeper than planned. This sense of security greatly reduces stress. The drill is an ordinary drill where you might see anywhere else with a slightly unusual shape, but please go to DENTECH booth at Dental show, pick one up, and give it a try.

- What are your expectations of us in the future?

- We hope that DENTECH keeps producing the highest quality of the product.

Please feel free to contact us first, as we can make prototypes only.

- Company

- DENTECH CORPORATION

- Address

- 53-5, Shimizu-cho, Itabashi-ku, TOKYO 174-0053, JAPAN

- Business Activities

- Manufacturing and sales of dental and surgical medical devices / Manufacturing and sales of veterinary medical devices

-

Contact by e-mail